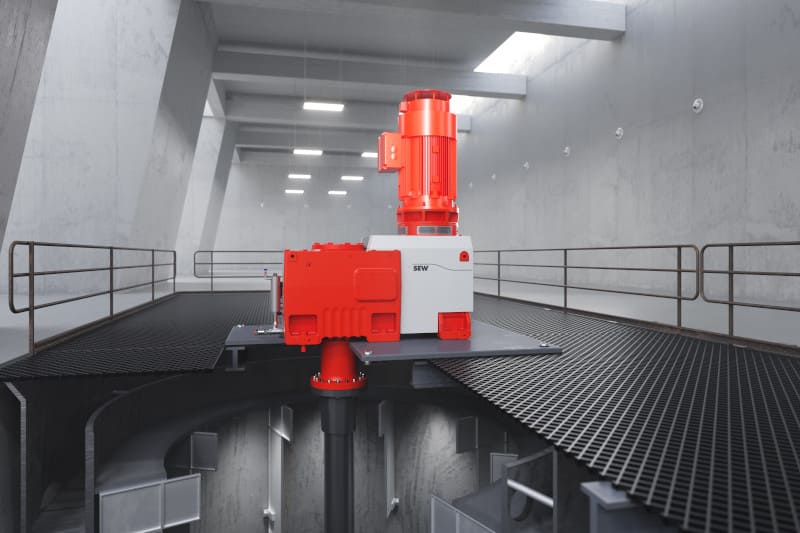

By launching an agitator design for the tried-and-tested X.e series, SEW EURODRIVE is expanding its product portfolio to include more application gear units designed for specific uses. The unit’s high permissible forces and bending moments as well as its maximum operational reliability make it the ideal solution for all high-performance agitators and mixers.

X.e-series agitator gear units can be used wherever high power ratings are required for stirring and mixing liquid or paste-type materials. The series is available in three sizes for a torque range of 117 to 217 kNm. As a three- or four-stage helical gear unit, it also covers gear ratios ranging from 20 to 400. The digital twin concept was applied throughout the entire design process, making it possible to simulate and optimize the mechanical components and oil flow in virtual reality. The end result is a drive specially designed for agitator applications that boasts high performance and maximum operational reliability.

Thanks to its application-specific rolling bearing concept with a large bearing spacing and its rigidity-optimized agitator housing, it is able to absorb the strong forces and bending moments that typically occur in agitation and mixing processes. Depending on the particular load scenario, there are three load-specific rolling bearing variants available for each size. Another stand-out feature of the gear unit is the particularly large output shafts, which are capable of withstanding the high bending moments. In other words, the agitator gear units in the X.e series can always be selected in the ideal dimensions for the application at hand.

When it comes to applications with a high thermal rating, there is the option of having a fan integrated into the motor interface. Air baffles on the gear unit housing ensure optimum air flow and, as a result, high cooling capacity. In many cases, this eliminates the need to invest in expensive, external coolers. Another feature of the agitator gear unit is its outstanding operational reliability. The gear unit housing is split horizontally, with the parting line located at the very top of the housing. The advantage of this design is that the parting line is always above the maximum oil level, meaning no oil can escape at the sealing surface of the two housing parts. The combination of a fail-safe drywell shaft seal and pressure lubrication also provides the user with additional operational reliability.

The agitator design of the X.e series pairs performance with maximum reliability. When combined with the versatility of the SEW modular motor system, this opens up new possibilities for customers to optimize high-performance agitators and mixers.